System Introduction

The silicon carbide substrate laser stripping system is a solution for achieving efficient stripping of silicon carbide substrates, capable of precise positioning, uniform processing, and continuous stripping of silicon carbide ingots. This equipment is suitable for silicon carbide substrates of different thicknesses and sizes. It integrates a complete set of functions such as surface grinding and thinning of silicon carbide ingots, laser modification, and complete peeling of thin wafers, achieving automatic and integrated operation. This effectively reduces the slicing loss of silicon carbide materials, increases processing speed, and contributes to cost reduction and efficiency improvement in the silicon carbide industry.

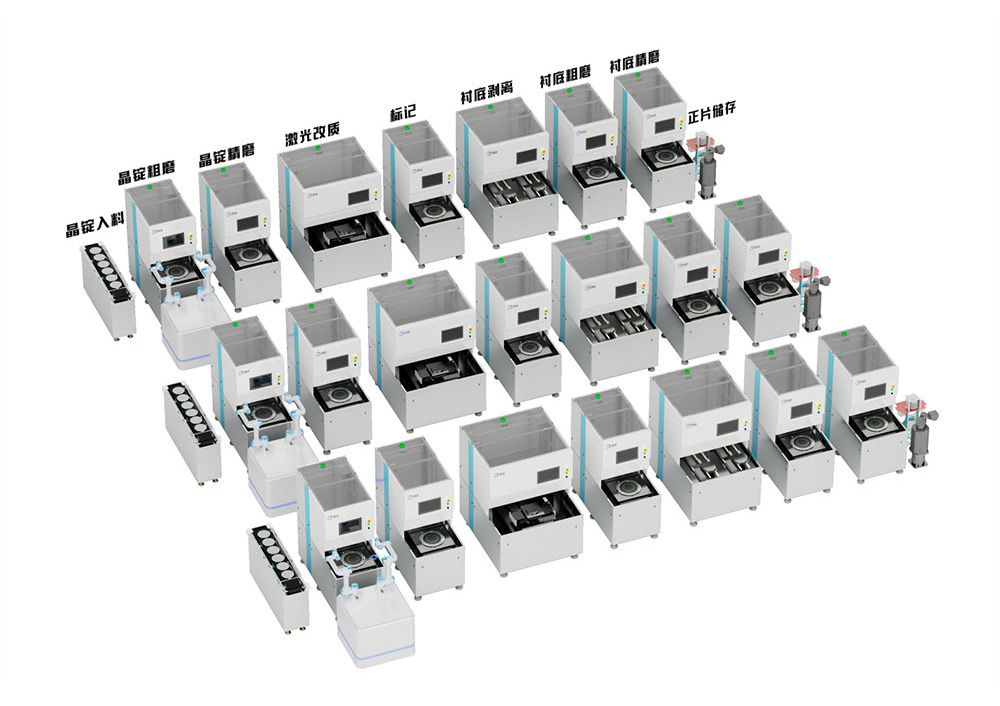

Discrete solution

Product features

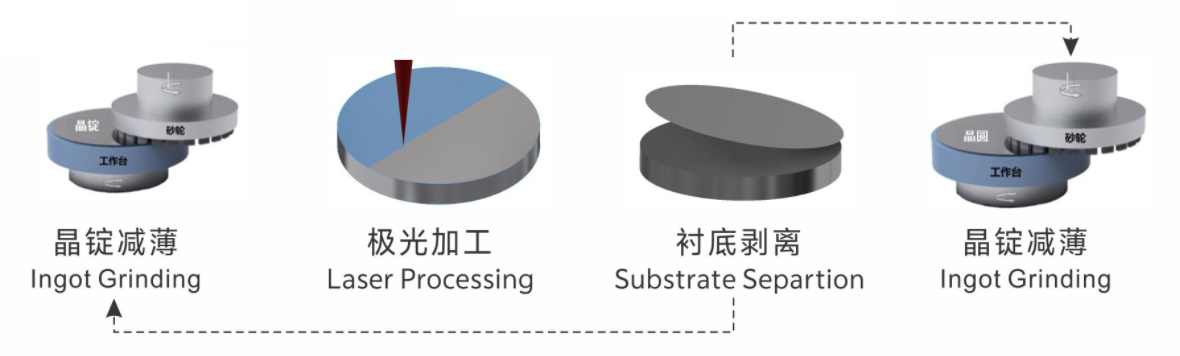

● The grinding machine takes into account both the full surface and the edge grinding of the ingot, with real-time online measurement function, precisely controlling the thinning thickness and flatness.

● Laser scribing modification is only carried out inside the ingot, effectively suppressing the generation of processing chips and improving the product quality of the wafer.

● The stripped crystal ingots are automatically returned to the grinding machine for grinding, with a high utilization rate of individual crystal ingots and high production efficiency.

● The surface of the stripped wafer is free of cracks, the side walls of the chips are smooth, and the luminous efficiency is high.

Laser stripping flowchart

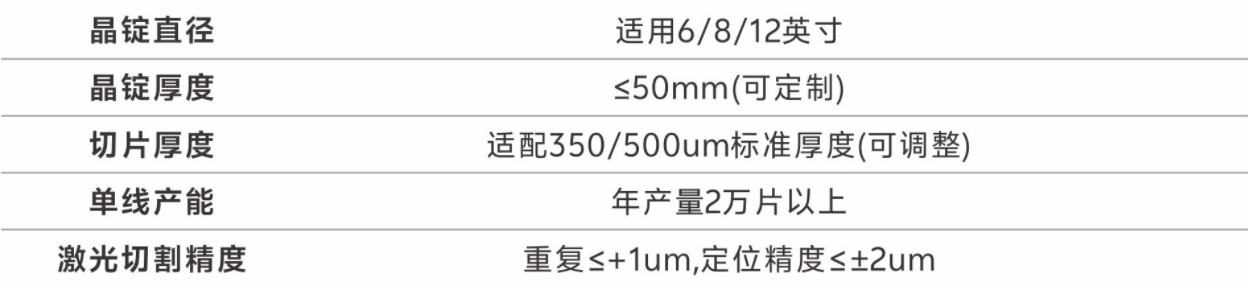

Main parameters